| Panel characteristics | Panel thickness [mm] | |||||||

| 50 | 75 | 100 | 150 | 200 | ||||

| Functions | · External walls

· partition walls · internal ceilings cover · objects insulation |

|||||||

| Standard Facings | · steel sheet coated with polyester paint, 25µm

· Aluminum sheet with Zn 50 – Zn 180g · stainless steel |

|||||||

| Steel thickness [mm] | 0.3, 0.4, 0.5, 0.6, 0.7, 0.8 | |||||||

| Rock wool core material | density 100 / 120 kg/m³ | |||||||

| Panel areal weight [kg/m²] | 15.50 | 18.50 | 22.5 | 30.00 | 36.50 | |||

| Thermal conductivity λD[W/mK] | 0.043 | |||||||

| Thermal transmittance

U-value [W/m²K] |

0,63 | 0,48 | 0,39 | 0,27 | 0,20 | |||

| Acoustic insulation [dB] | 27 | |||||||

| Length [mm] | As customized | |||||||

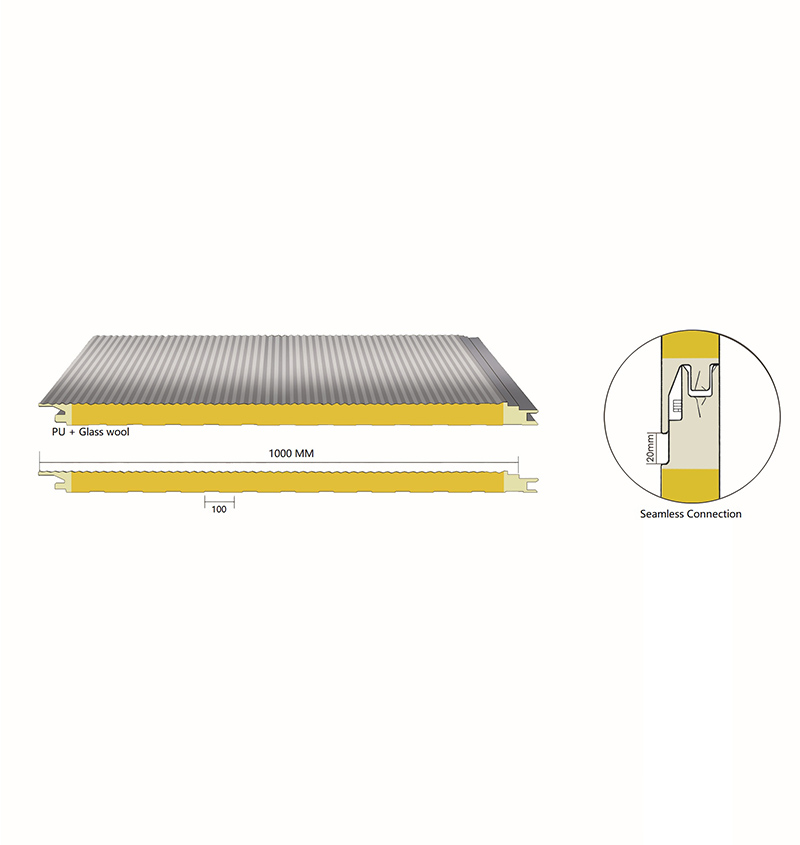

| Effective width [mm] | 1000mm(option 950,1150) | |||||||

| Reaction to fire | – | A2-s1, d0 and NRO | ||||||

| Fire resistance | – | EI 90 / E 120 | E 120 / EW 60 | |||||

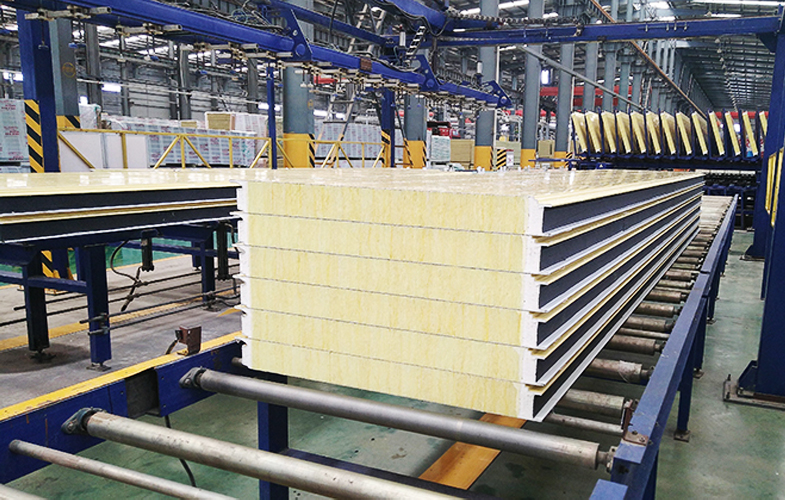

Rock wool core material: the density of 120kg / m3; rock wool block staggered laying, the fiber direction perpendicular to the sandwich is still under the surface, and closely Detailed enrich the entire vertical and horizontal surface movement plate. And wool and, through the high intensity blowing agent connections between the lower plate is formed integrally between rock wool blocks. Sophisticated production process to ensure to produce high density rock wool insulation between the body and the metal plate inside the inner wall of strong adhesion, so that the rock wool sandwich panel has good stiffness.